Hazardous Gas Monitoring System

Hazardous Gas Monitoring System Specification

- Resolution

- 1 ppm

- Measurement Range

- Configurable as per gas type

- Capacity

- Multiple channel capability

- Humidity %

- 0 to 95% RH, Non-condensing

- Diameter

- 120 mm (enclosure)

- Frequency

- 50 Hz

- Temperature Range

- -10C to +55C

- Application Media

- Hazardous or Toxic Gases

- Sensor Type

- Electrochemical / Catalytic / Infrared (depending on target gas)

- Protection

- IP65 Enclosure

- Current Range

- 4-20 mA

- Pressure Range

- 0.9 to 1.1 atm

- Connectivity Type

- RS485 MODBUS / 4-20 mA Output

- Material

- Powder-Coated Mild Steel / SS-304

- Power Supply

- 230 V AC 10%, 50 Hz

- Power Consumption

- < 5 W

- Accuracy

- 1% of Full Scale

- Display Type

- Digital LCD Display

- Range

- 0 - 1000 ppm (customizable for specific gases)

Hazardous Gas Monitoring System Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 30 Units Per Month

- Delivery Time

- 2-7 Days

- Main Domestic Market

- All India

About Hazardous Gas Monitoring System

Key Features

- Real-time Gas Detection

- Wireless Connectivity

- Cloud-Based Data Storage

- Remote Monitoring and Control

- Integration with Existing Systems

- Battery-Powered Sensors

Our IoT sensors continuously monitor the industrial environment, providing real-time data on hazardous gas levels. Instant alerts are triggered if gas concentrations exceed safe thresholds, allowing immediate response and mitigation.

The system operates on a wireless network, enabling easy deployment and scalability. No more messy wiring or complex installations, ensuring a hassle-free setup.

All the gas monitoring data is securely stored in the cloud, enabling easy access and analysis from anywhere, at any time. Historical trends and patterns can be analyzed to optimize safety protocols.

Through a user-friendly interface accessible on any device, managers and safety personnel can remotely monitor gas levels, receive alerts, and take necessary actions, even when off-site.

Our solution seamlessly integrates with your existing safety and automation systems, enhancing their capabilities and providing a holistic approach to safety management.

The IoT gas sensors are equipped with long-lasting batteries, ensuring uninterrupted monitoring even during power outages.

Benefits

- Enhanced Safety

- Compliance and Regulations

- Reduced Downtime

- Cost-Effective Solution

- Peace of Mind

By detecting hazardous gas leaks early, our system minimizes the risk of accidents, ensuring the safety of your workers and the surrounding environment.

Stay ahead of industry regulations and compliance requirements with comprehensive gas monitoring data readily available for reporting and audits.

Swift response to gas leak incidents helps avoid prolonged shutdowns, saving valuable production time and minimizing financial losses.

Our IoT-based monitoring system eliminates the need for expensive manual monitoring and ensures efficient resource allocation for gas safety measures.

With 24/7 monitoring and immediate alerts, you can have peace of mind, knowing that your workforce and assets are protected at all times.

Versatile Alarm and Data Features

This gas monitoring system offers both buzzer and relay outputs, enabling immediate on-site and external alarm activation. Its internal memory can log up to one year of historical data, providing valuable records for safety audits and compliance. Data can be accessed locally through a digital LCD display, or remotely when an optional Ethernet module is installed.

Rugged Design for Industrial Environments

Engineered with an IP65-rated enclosure made of powder-coated mild steel or SS-304, this device is suitable for harsh or challenging workplaces. Wall-mounting capability saves floor space, while user-friendly soft keys and a touch keypad facilitate quick operation. The customizable measurement range and channel capacity allow adaptation to varying gases and site-specific requirements.

Precision Monitoring and Ease of Use

With accuracy up to 1% of full scale and fast detection (under 30 seconds), this system ensures early warning for safety. On-site zero and span calibration simplify maintenance, allowing personnel to adjust readings as needed. The LCD backlit display, along with English and configurable language support, guarantees clarity and ease of use in diverse industrial settings.

FAQ's of Hazardous Gas Monitoring System:

Q: How do I install the Hazardous Gas Monitoring System?

A: The system is designed for wall mounting using the provided PG gland or cable connector for secure cable entry. Its compact, rugged enclosure is suitable for various industrial settings.Q: What gases can the system detect, and is the range configurable?

A: The system can monitor a variety of hazardous or toxic gases using electrochemical, catalytic, or infrared sensors, depending on the target gas. The measurement range is configurable, with a typical default range of 0-1000 ppm.Q: When should calibration be performed, and how is it done?

A: Routine calibration is recommended as per site safety protocols or manufacturer guidelines. On-site zero and span calibration can be easily performed using the soft key/touch keypad interface, ensuring maximum accuracy.Q: Where is the logged data stored, and how can it be accessed?

A: Logged data is stored internally, capable of maintaining up to a year's history. Data can be viewed directly on the LCD display; for remote access, an Ethernet module can be added to enable retrieval from a distance.Q: What are the usage benefits of the alarm outputs?

A: The system provides both buzzer and relay outputs. This dual design allows for immediate onsite alert via buzzer and external notifications or actions (like activating exhaust fans) via relay for enhanced safety.Q: How does remote access functionality work?

A: Remote access is available as an optional feature through an Ethernet module. This allows authorized personnel to monitor and manage the system's data and alerts from a control room or offsite location.Q: What makes this monitoring system suitable for Indian industries?

A: It operates on a 230V AC, 50 Hz supply compatible with Indian standards, supports multiple languages, and is available through manufacturers, service providers, and suppliers across India, making it an adaptable and accessible solution for local industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Smart Devices Category

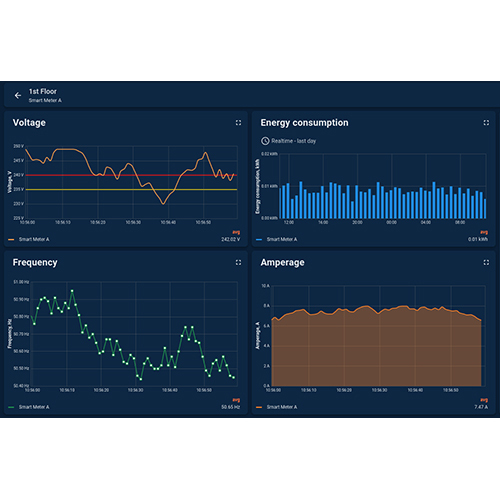

Energy Monitoring System

Price 14000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Usage : Industrial

Color : Black

Size : Different Size

Carbon Monoxide Monitoring System

Price 13500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Usage : Industrial

Color : White

Size : Different Size

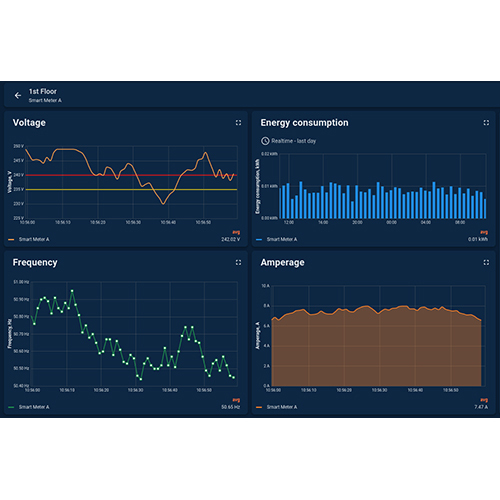

Smart Energy Monitoring System

Price 14000 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Metal

Usage : Industrial

Color : Black

Size : Different Size

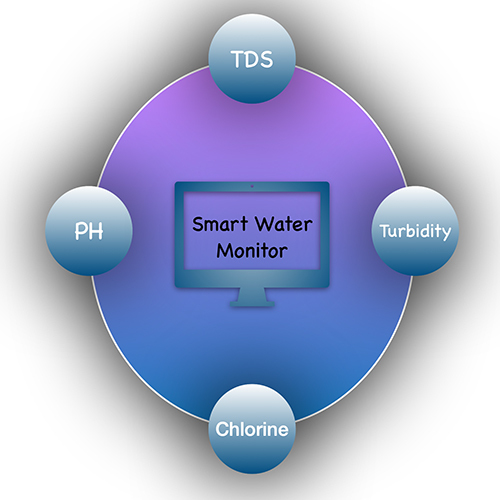

Smart Water Quality Monitoring System

Minimum Order Quantity : 1 Unit

Material : Metal

Usage : Industrial

Color : Silver

Size : Different Size